Have you ever imagined that one day your sportswear fabric could charge your phone? Or that a lightweight mask could monitor your respiratory health in real time? With the rapid development of 5G and artificial intelligence, smart wearable devices are integrating into daily life. However, providing them with lightweight, environmentally friendly, and long-lasting power sources remains a global focus. Flexible thermoelectric materials can directly convert human body heat or environmental waste heat into electricity. Yet, due to the less-than-ideal performance of these materials, the conversion efficiency of thermoelectric devices has been relatively low, limiting their large-scale application in the field of wearable electronics.

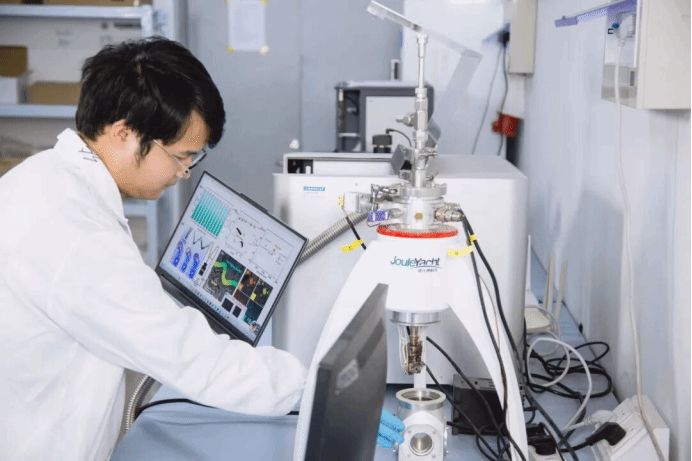

Recently, Qin Jie, a Class of 2023 PhD student in the Faculty of Materials Science and Technology at Shanghai Institute of Technology, under the guidance of his supervisors Professor Ke Qinfei and Professor Du Yong, innovatively adopted solution 3D printing technology to successfully prepare polymer-coated silver selenide-based flexible thermoelectric films. This material achieved a power factor of 2191.5 μW m⁻¹ K⁻² at 400 K, setting a new performance record for flexible organic/inorganic composite thermoelectric films fabricated via 3D printing.

This performance leap was no accident. The core key lies in the team's precise control over the material's "microstructure." "By synergistically regulating the heterogeneous interfaces, pores, grain boundaries, and dislocations within the material – much like 'fine-tuning' an instrument – we simultaneously enhanced both the Seebeck coefficient and electrical conductivity (core parameters measuring thermoelectric conversion capability), while effectively reducing the thermal conductivity," explained Qin Jie.

More notably is the material's "flexible performance": after 1000 repeated bending cycles, its power factor retention rate remained above 93%. This makes it suitable for the skin-contact and bending scenarios of smart wearable devices, addressing the longstanding challenge of balancing "high performance" with "high flexibility."

"Interdisciplinary integration was key to achieving this breakthrough," Qin Jie noted. He introduced that Professor Ke Qinfei has extensive research experience in polymer design, providing crucial guidance for improving the material's flexibility and stability, while Professor Du Yong has deep expertise in the preparation and performance study of thermoelectric materials and devices. Their complementary perspectives created advantages in merging the polymer and inorganic systems.

"We combined the flexibility advantages of polymer materials with the energy conversion capability of thermoelectric materials, breaking through the research limitations of a single discipline. This is not only a technological innovation but also a vivid practice of interdisciplinary integration," emphasized Professor Ke Qinfei.

Building on the material breakthrough, the team further achieved integrated "material-to-device" fabrication. Traditional processes require multiple complex steps like cutting, welding, and encapsulation to create a thermoelectric device, which is inefficient and costly.

Professor Du Yong pointed out: "Using solution 3D printing technology, we print the thermoelectric device integrally. This provides a brand-new technical pathway for the scalable manufacturing and future industrial promotion of flexible thermoelectric materials and devices."

Guided by the "Material – Process – Device – Application" framework, the team established a closed-loop model for cultivating scientific research capabilities. "During the thermoelectric ink formulation design and synthesis process, we strengthened the 'composition-structure-performance' correlation. In optimizing the printing process, we focused more closely on demand orientation, emphasizing the cultivation of students' engineering thinking," said Professor Ke Qinfei. This full-chain practice not only produces results but also cultivates students' awareness of diverse innovation and their ability to solve practical problems.

Currently, this technology has demonstrated practical value in multiple scenarios: Attaching the flexible thermoelectric device to the skin surface can continuously convert body heat into electricity; the team's developed smart mask can monitor breathing frequency and patterns in real-time by detecting temperature difference signals generated by breathing, offering new approaches for the daily management of respiratory diseases like asthma; the flexible thermoelectric device can even generate differential electrical signals when fingers touch different areas, enabling intelligent "position recognition."

"These are not just 'samples' in the laboratory, but also 'product prototypes' with the potential to solve real-life problems," said Professor Du Yong. He stated that this research innovation not only demonstrates the university's original achievements in this research field but also expands the application scenarios of flexible thermoelectrics in the smart wearable domain.

Based on Shanghai Institute of Technology's educational philosophy of "Prospering through Industry, Strengthening through Technology," the team is planning to collaborate with the university's leading discipline of Fragrance and Flavor Science to explore "functional aromatic new materials." Professor Ke Qinfei revealed that in the future, natural plant fragrances might be incorporated into the thermoelectric materials to achieve multiple functions like "emotional fragrances," aiming to "make smart materials not only 'useful' but also 'warm' and 'fragrant'."

Currently, this research result has been published in the top international journal Nature Communications (2025, 16, 8497). The first author of the paper is Qin Jie, a PhD student from the Class of 2023 in the Faculty of Materials Science and Technology at Shanghai Institute of Technology. The corresponding authors are Professor Du Yong, Professor Ke Qinfei, and collaborating author Professor Hong Min from the University of Southern Queensland, Australia.

"Scientific research isn't distant and unattainable; it's like 'magic' that can solve everyday troubles and make life better," Qin Jie added. In the future, he will continue to delve deeper into the field of flexible thermoelectric materials and devices, striving to produce more results with originality and application value, hoping to let more people experience the charm of thermoelectric technology.